Cerakoting your Silencer

You may have seen Cerakote on rifles and accessories before, but it isn’t as common on silencers. Silencers, or suppressors, get significantly hotter than guns do. The added heat can cause normal Cerakote to wear much more quickly than anticipated, so most people avoid it.

So, what do you do? If you go to a certified Cerakote shop like our partner Culper Precision, they can direct you to the more heat-resistant Cerakote colors!

For use on Rifles and parts that don’t get as hot, they will use the H series of Cerakote. The H series has a large variety of color options and is commonly used for artistic paint jobs. On Cerakote’s website, they have 136 color options listed for the H series.

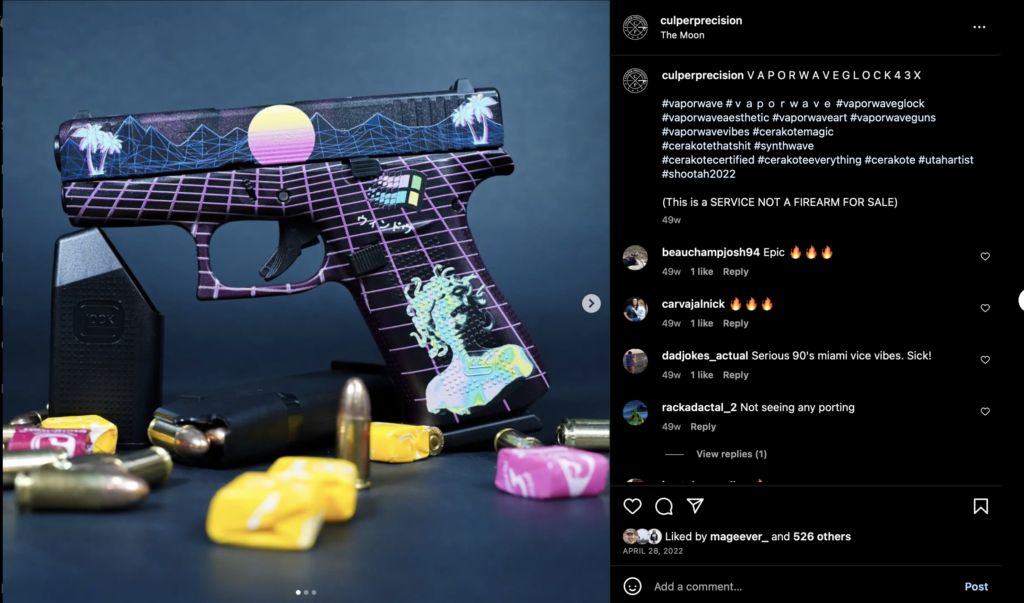

Culper Precision Vaporwave H series Cerakote on a Glock 43X https://www.instagram.com/p/Cc6saL1rxGJ/

For suppressors, they will use the C series of Cerakote, which is much more heat resistant but may not have as many options. Cerakote has 43 options listed for C Cerakotes.

Culper Precision’s version of Multicam Black from the Culper Custom Shop using the C series of Cerakote

Before and after of the Dead Air Silencers Nomad LTi

Certified Cerakote shops will tape off all the appropriate spaces to make sure they don’t get paint where they don’t want it. Here you can see that the threads on the direct thread adapter are nice and shiny with no spots of Cerakote.

On guns, they will frequently disassemble the gun fully to remove any parts that they don’t want to get paint on. Normally, they will remove magazine releases, charging handles, bolt releases, etc.

If you’re thinking of getting a silencer, gun, or anything else cerakoted, give us a call! We have a partnership with Culper Precision for their Cerakote and slide milling services. We will handle all the transfers and show you a gallery of their work, to make your dream paint job become a reality!